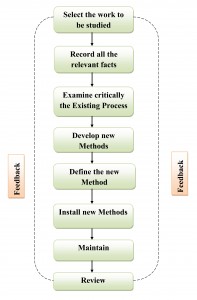

Method Study Procedure

This procedure involves seven basic steps as follows :

1. SELECT

Select the work to be studied and define its boundaries. There are three factors that should be kept in mind when selecting a job.

i. Economic Factor

It is obviously a waste of time to start or to continue a long investigation if the economic importance of a job is small,or if it is one that is not expected to run for long. The economic importance of the job must be of such magnitude that it is worthwhile to begin a method, study of the job or to continue it. Bottlenec1cs in production, too much movement of materials in the operation, idle machines, idle operators and high costs of operations are the usual. choices. The preferences should be given to the job with the greatest potential savings. No job should be selected for the method study, if it is expected to run only for a short time.

ii. Technical Factor

One of the important considerations is the desire by management to acquire more advanced technology,whether in equipment or in processes.Thus management may want to computerize its office paperwork or its inventory system,or to introduce automation in the production operations.

ii. Human Factor

Certain operations are often a cause of dissatisfaction by workers.They may induce fatigue or monotony or may be unsafe or clumsy to operate.The level of satisfaction should point to a need for method study.Thus an operation which may be perceived as effective by management may,on the other hand,generate a great deal of resentment by the workforce.If such operations are addressed by work study specialists as part of an overall work study programme,the benefits of work study can become more apparent to the workforce. In selecting a job. human reactions should be given due-consideration. The relation between management and the workers must not be strained. Unpopular and tiresome jobs should be studied with improved functions. The workers will eventually accept method study if the unpleasant features of these unpopular jobs are removed from them by the application of method study

2. RECORD

Record all the relevant facts about the present method by direct observation and collect such additional data as may be needed from appropriate sources.The main aims of recording are:

i. To obtain adequate and accurate information.

ii. To present the facts in a concise and comprehensible form for analysis.

iii. To submit proposals to management in a way which is easily understood.

iv. To provide,eventually,detailed operating instructions for the use of supervisors and operators.

Types of Recording Techniques

The recording techniques generally used are as follows :

(a) The Operation Process Chart

(b) The Outline Process Chart

(c) The Flow Process Chart (material)

(d) The Flow Process Chart (man)

(e) The Multiple Activity Chart

(f) The -Two Handed Process Chart

(g) The Simultaneous Motion Cycle Chart (8IMO Chart)

(h) The Flow Diagram

(i) The String Diagram

(j) The Travel Chart

3. EXAMINE

Examine the way the job is being performed and challenge its purpoe,place,sequence and method of performance. When the details of the existing method have been recorded through a, suitable process chart, the next step in’ the study procedure is to examine all the facts. Critical Examination. of the recorded, data is the crux of method study. I t is at this stage that the possible alternatives for each activity are evolved for later development. Each activity is questioned and challenged thoroughly with a view to improving the situation. Critical Examination consists of a well designed questioning pattern in an impartial and objective manner.

4. DEVELOP

Develop the most practical, economic and effective method having due regard to all contingent circumstances. various alternatives would have. been evolved for each activity during the examination stage and depending on the implications, some of the alternatives be chosen for development. Under each governing considerations like purpose, means, ‘ ,sequence, place and person there may be any number of suitable alternatives generated. In developing the new method the economics and productivity of these suggestions when the job is viewed as a whole must be determined. Each of the developed methods’ would have to be again evaluated and the best chosen for implementation. In determining the best method, economic considera- 40 tion such as, cost of implementation and expected savings, feasibility; acceptance and reaction of employees would all have to be taken into account.

5. DEFINE

Define the new method in a clear manner and present it to those concerned,i.e management,supervisors and workers.After the proposal plan is finalized,it is reduced to writing to provide continous guidance to the key persons in the organization. The written standard practice should give a clear description of

(I) the diagram of work place layout and if possible, the sketches of special tools, jigs or fixtures

(2) the tools and equipments to be used,

(3) general operating conditions

(4) a description of new method. The. details of description of new method will depend on the nature of the job and the volume of production

6. INSTALL

Install the method as standard practice and train the persons involved in applying it.The implementation is successful if the top management has developed faith and interest in the new plan and can motivate the personnel down the line. Installation will require the active support of all concerned and it is by no means a simple job.

7. MAINTAIN

Maintain the method by regular routine checks.Introduce control procedures to prevent a drifting back to the previous method of work.The top leaders must learn the art of dealing with the interest groups and the pressure groups,who may oppose the running of the new method on flimsy grounds. e, when the new method is operating. detailed supervision is necessary until managements are satisfied that the scheme is operating satisfactorily. Unless the new method is observed for some time after installation the expected results may not be reused. Changes may creep in which lead to. a less of efficiency and external conditions may alter. On the other hand some changes may improve efficiency and will show up in operation. Therefore, during the ‘maintain’ period reviews are carried out at the necessary frequency in order to see that the planned results are achieved and if possible improved.

8. Review

The main aim of reviewing is to discover whether there are any discrepancies between authorized procedure and current practice at the time of review.Reasons for any variation in the method must be investigated.Where the review reveals that there are undesirable variations in the method,measures should be taken through supervision to ensure that the method reverts to the authorized procedure.