3. Stationary Layout/Fixed Position Layout

This type of layout is used in those situations where the semi-finished and finished goods are of such a size and weight that their movement from one place to the other is not possible. Here men, equipment and the raw-material is moved to a place where all the manufacturing activities are carried out e.g. ship-building, manufacturing of locomotives, job-welding shops, construction of dams and bridges etc.

Advantages

i. Investment is relatively less.

ii. Labour as well as machine can be used for a wide variety of operations producing different products.

iii. Labourers and workers can be employed and remain busy throughout the process in one work or the other.

Disadvantages

i. Materials handling cost is high.

ii. Special purpose equipments are required.

iii. Layout may change with the change in product.

iv. Lead-time may increase for each and every operation.

v. Process time is very high.

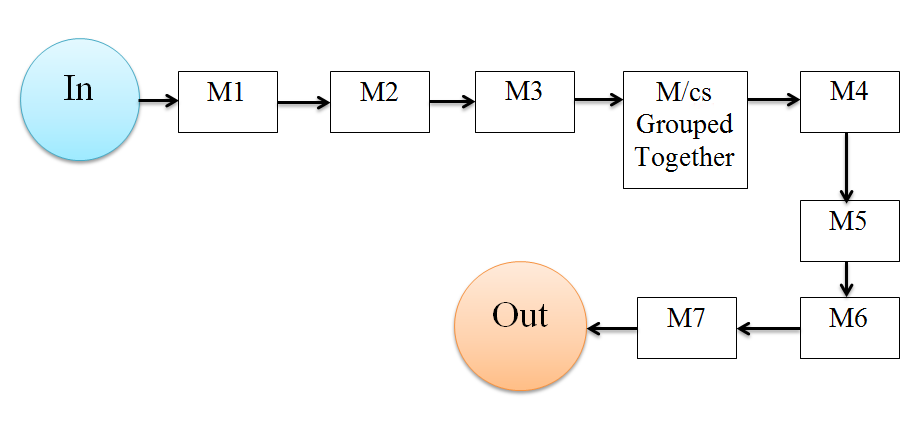

4. Combined Layout

Because of the obvious advantages and limitations of each of the above methods a combination of any two or all of them is finding more and more application in the present day. When the process and product layouts are combined to get a said benefit, it is called the combined layout, as shown in the following figure. It is possible to have both the types of layout in an efficiently combined form if the products manufactured are somewhat similar and not complex; group layout is a combined form of a product and process layouts. In certain batch production industries, a variety of products are assembled. Product layout is employed for mass production of common components. In addition, the process layout is used for assembly the standard components in batch of products. In soap manufacturing plants, the machinery for manufacturing soap is laid out in a straight line. But the various ancillary facilities, like heating, power house, glycerine plant and water treatment plant are arranged on a functional basis. Thus, this type of layout is a blending of the product-based and process-oriented layouts.

Advantages

i. Investments are relatively high.

ii. Use the benefits of process and product layout.

iii. Optimum utilization for machines and equipments is done.

Disadvantages

i. Materials handling cost is less.

ii. Flexibility is less.

5. Cellular Manufacturing Layouts

It is a special type of functional layout in which the facilities are clubbed together into cells. This is suitable for systems designed to use the concepts, principles and approaches of ‘group technology’. Such a layout offers the advantages of mass production with high degree of flexibility. We can employ high degree of automation even if the number of products are more with flexible requirements. In such a system the facilities are grouped into cells which are able to perform similar type of functions for a group of products.

According to V.B. Solaja

Group technology is the technique of identifying and bringing together related or similar parts in a production process in order to utilize the inherent economy of low production methods.

Advantages

i. Material flow is significantly improves, which reduces the distance traveled by inventory.

ii. Reduces cumulative lead times.

iii. Cellular manufacturing is most suitable for batch manufacturing.

iv. Part movement time, set-up time, and wait time between operations are reduced.

v. Considerable reduction in WIP inventory freeing idle capital that can be better utilized elsewhere.

Disadvantages

i. Implementing cellular manufacturing could lead to a decrease in manufacturing flexibility.

ii. It is felt that conversion to cells may cause some loss in routing flexibility, which could then impact the viability of cell use.

iii. Obtaining balance among cells is also more difficult than for flow or job shops.

iv. If demand diminishes greatly, it may be necessary to break up that cell and redistribute the equipment or reform the families.